Mid-Tech designs air compressor and vacuum pump systems and is an authorised distributor for leading compressor and vacuum pump brands, including CompAir, Hydrovane, Gardner Denver, Elmo Rietschle, Champion and Reavell. In choosing air compressor and vacuum systems, there are various ways to look at your needs. One way is size. Does your business need a small, portable unit or do you have a large industrial requirement? Another is oil lubricated versus oil-free. As experts, we know which models are best for your applications demanding compressed air or vacuum.

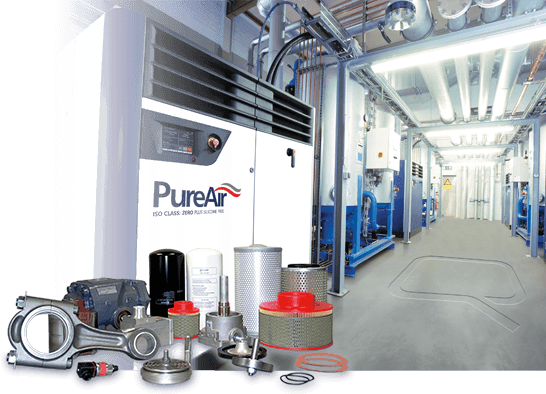

Mid-Tech has the design, installation and service expertise, as well as the expert advice in making the right decision about the type of air compressors and pumps you need. Air compressors pressurise air to a prescribed level and then deliver the compressed air in a steady steam as a source of power for pneumatic tools and machines. There are different types of systems for different applications.

When you choose a system, power, efficiency, and maintenance are primary factors that need to be considered. There are different types of air compressor and vacuum solutions – knowing which will suit your application best and be the most efficient is where Mid-Tech deliver.

Both the rotary screw and rotary vane systems have been in operation since the mid-20th century. The rotary vane has a rotor with longitudinal slots with sliding blades or vanes, rotating inside a cylinder, As the rotor turns, centrifugal force pushes the vanes against the cylinder, compressing the air. A screw compressor consists of two parallel rotors which intersect longitudinally, inside a cylinder. As the rotors turn together, the meshing motion compresses the air.

A piston, or reciprocating, compressor uses valves and piston rings. The piston are run by a crankshaft. They are larger than rotary compressors and run hotter. Running hotter, they tend to retain more moisture. In a screw compressor there are two moving parts while the piston compressor has more moving parts.

There are also lubricated and oil-free versions of these systems. The decision on which type to use depends on the use of the compressed air they produce. In clean environments, such as food production, where 100% clean air is necessary, oil free compressors may be the preferred choice.

Whatever your industrial needs and applications, Mid-Tech has the expertise to maintain, service and repair your compressed air and vacuum systems.

Mid-Tech provides flexible service agreements to suit your needs and systems regardless of their working environment. We also offer one-off service deals for your convenience. We have the parts, tools and expertise you need. Same day call-out response is available. For more information on our services, call 0800 028 8366 or contact us here.

Read Less...